Global Quartz Crystal Oscillator Market - Industry Dynamics, Market Size, And Opportunity Forecast To 2030

Report ID: MS-649 | Energy and Natural Resources | Last updated: Mar, 2025 | Formats*:

Quartz Crystal Oscillator Report Highlights

| Report Metrics | Details |

|---|---|

| Forecast period | 2019-2030 |

| Base Year Of Estimation | 2024 |

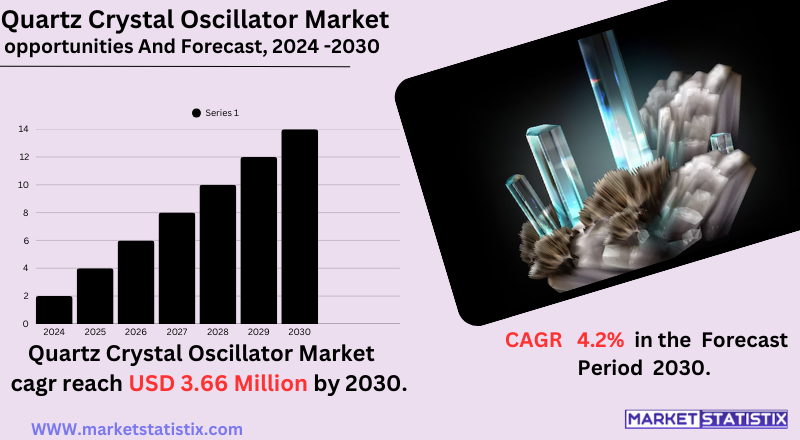

| Growth Rate | CAGR of 4.2% |

| Forecast Value (2030) | USD 3.66 Billion |

| By Product Type | Temperature-Compensated Crystal Oscillator (Tcxo), Voltage-Controlled Crystal Oscillator (Vcxo) Frequency-Controlled Crystal Oscillator (Fcxo), Oven Controlled Crystal Oscillator (Ocxo), Simple Packaged Crystal Oscillator (Spxo), Others |

| Key Market Players |

|

| By Region |

Quartz Crystal Oscillator Market Trends

The rapid evolution of wireless communication technologies like 5G and IoT is thus a primary catalyst for growth within the field of frequency control, requiring superior stability and accuracy. Increasingly sophisticated consumer and automotive systems as well as industrial automation products, for which optimum performance is based on precise timing, also maintain the drive of growth in this market. Miniaturization of electronic devices and lower power consumption requirements furnish the other avenues for innovation and adoption of advanced quartz crystal oscillators. Further fuelling the demand for high-performance oscillators has been the increasing adoption of advanced technologies in autonomous vehicles and high-speed data networks. These applications demand extremely stable and reliable timing signals. In addition, industries where high data accuracy and integrity have become a pressing factor, such as finance and telecommunications, further amplify the driving force for precise timing solutions.Quartz Crystal Oscillator Market Leading Players

The key players profiled in the report are Siward Crystal Technology (Taiwan), Txc Corporation (Taiwan), Murata Manufacturing (Japan), Miyazaki Epson Corporation (Japan), River Eletec Corp. (Taiwan), Hosonic Electronic (Taiwan), Daishinku Corp. (Japan), Kyocera Crystal Device (KCD) (Japan), Mercury Electronic (Taiwan), Oscilloquartz SA (Switzerland), Nihon Dempa Kogyo (NDK) Co. LTD. (Japan), Rakon Ltd. (New Zealand), Vectron International (United States)Growth Accelerators

The market for quartz crystal oscillators can be classified into several circuits depending on the application. Temperature-Compensated Crystal Oscillator (TCXO) would seek to maintain the oscillation frequency independent of temperature changes, which are suitable for applications including Bluetooth, Wi-Fi, and smart metering. Simple Packaged Crystal Oscillator (SPXO) usually does not include temperature control and instead offers basic frequency stability. Most SPXOs are used in real-time clock microcontrollers for laptops, smart devices, or other consumer electronics. Frequency could be altered by an external voltage in a Voltage-Controlled Crystal O. Continue reading. As time-controlled crystal oscillators, OCXOs provide very high stability in frequency since they keep the crystal at a constant temperature; this is for very high-precision applications such as aerospace, defense, and scientific instrumentation. In terms of mount types, the market can be divided into categories of surface mount and thru-hole. The Surface Mount Technology (SMT) has been put high on the list of the compact size and possibility of being put together automatically, making it multiply used in consumer electronics, telecommunications equipment, and automotive electronics. This creates possibilities of high-density circuit designs and efficient mass production. In that regard, Thru-Hole, which is the traditional mounting technique, involves inserting component leads through pre-drilled holes on printed circuit boards, providing very strong mechanical stability. This technique is preferred in applications where components are subjected to mechanical stress and exposure to extreme environmental conditions, including aerospace and defense systems, where durability and reliability are very critical.Quartz Crystal Oscillator Market Segmentation analysis

The Global Quartz Crystal Oscillator is segmented by Type, Application, and Region. By Type, the market is divided into Distributed Temperature-Compensated Crystal Oscillator (Tcxo), Voltage-Controlled Crystal Oscillator (Vcxo) Frequency-Controlled Crystal Oscillator (Fcxo), Oven Controlled Crystal Oscillator (Ocxo), Simple Packaged Crystal Oscillator (Spxo), Others . The Application segment categorizes the market based on its usage such as Consumer Electronics, Military and Aerospace, Industrial, Automotive, Telecom and Networking, Medical Equipment, Others. Geographically, the market is assessed across key Regions like {regionNms} and others, each presenting distinct growth opportunities and challenges influenced by the regions.Competitive Landscape

Mergers and acquisitions have brought about substantial consolidation in the quartz crystal oscillator market, with the intent of increasing both technological strength and wider reach. In December of the year 2023, SiTime Corporation took ownership of clock products and licensed clock IP from Aura Semiconductor, thus adding 20 high-quality clocks to its treasure chest. According to the company, it has plans to introduce an additional 20 high-quality clocks by the end of 2024. Thus, this is a strategic move by SiTime to become a sole supplier of differentiated precision timing products. In July 2023, TXC Corporation acquired Vectron International. Vectron is the leading provider of miniature quartz crystal oscillators and filters. The acquisition has augmented TXC's product portfolio by making it possible for TXC to penetrate deep within the industrial and medical electronics markets. Further, in March 2021, Abracon concluded its acquisition of AEL Crystals; this is a frequency control supplier with its headquarters in Surrey, England. Thus, these consolidations show how much the industry's trend is focused on fine-tuning technological expertise and broadeningChallenges In Quartz Crystal Oscillator Market

The recent emergence of 5G infrastructure, IoT devices, and autonomous driving systems has led to the demand for highly efficient low-power oscillators and high-performance oscillator systems. The military and aerospace sectors also stoke demand for high-end oscillators that can withstand the rigors found in challenging environments. Emerging markets with accelerated growth in the Asia-Pacific region are complemented by the rapid advancement of consumer electronics and government support for technological advancement. Regionally, North America remains the largest of the markets owing to its established electronics industry and high demand from military applications, while the Asia-Pacific region is projected to grow at the fastest rate owing to increased production of electronic devices in countries such as China and South Korea alongside investments being made in 5G technology and smart city projects. Europe makes a significant contribution as well from automotive electronics and telecommunications infrastructure. The various dynamics seen across the regional markets clearly highlight the global opportunities for quartz crystal oscillators as industries keep adopting advanced technologies that seek precise timing solutions.Risks & Prospects in Quartz Crystal Oscillator Market

A very important trend is the strong push towards miniaturization. As devices become smaller and more compact, the demand for equally small and efficient oscillators rises. The consumer electronics sector particularly highlights this need, which includes smartphones, wearables, and other portable devices that call for tiny, high-performance components. Also, the quick rollout of 5G networks generates a very strong demand for oscillators of high stability and precision, as accurate timing is necessary for the optimum performance of these networks. Another noteworthy trend is the increasing adoption of quartz crystal oscillators in the automotive industry. With advanced driver-assistance systems (ADAS) and autonomous vehicles, the need for accurate and reliable timing solutions is becoming paramount. These systems depend on precise timing for the synchronization of sensors and data processing, thus creating a demand for high-quality oscillators. These trends push manufacturers to invest in R&D focused on improving frequency stability, lowering power consumption, and enhancing quartz crystal oscillator performance in general.Key Target Audience

The quartz crystal oscillator market caters to quite a number of industries that need precise frequency control and timing solutions. Key target audiences include the telecommunications and networking sector, which, around 40%, owned the market share in 2024. The dominance here is created with crystal oscillators being deployed in the infrastructure equipment such as base stations, data centers, and fiber optics, especially in the global rollout of 5G networks that have high precision timing component requirements.,, Another significant segment is occupied by the automotive industry, which is put at about a 3% growth projection during 2024-2029. With increasing vehicle electronics—ADAS, LiDAR, and infotainment systems—this forecast is getting bullish. Other sectors like consumer electronics, industrial applications, aerospace and defense, and healthcare are also vital markets. A variety of quartz crystal oscillators are used in production for devices from smartphones and wearables to medical equipment and navigation systems, demonstrating the versatility of the component across many applications in technology.Merger and acquisition

The quartz crystal oscillator market caters to quite a number of industries that need precise frequency control and timing solutions. Key target audiences include the telecommunications and networking sector, which, around 40%, owned the market share in 2024. The dominance here is created with crystal oscillators being deployed in the infrastructure equipment such as base stations, data centers, and fiber optics, especially in the global rollout of 5G networks that have high precision timing component requirements. Another significant segment is occupied by the automotive industry, which is put at about a 3% growth projection during 2024-2029. With increasing vehicle electronics—ADAS, LiDAR, and infotainment systems—this forecast is getting bullish. Other sectors like consumer electronics, industrial applications, aerospace and defense, and healthcare are also vital markets. A variety of quartz crystal oscillators are used in production for devices from smartphones and wearables to medical equipment and navigation systems, demonstrating the versatility of the component across many applications in technology. >Analyst Comment

The quartz crystal oscillator market is on a steady growth platform, which is mainly driven by the demand for precision timing solutions in most electronic devices. Some of the key market drivers include the proliferation of consumer electronics, the expansion of telecommunication infrastructure (especially 5G), and the growing adoption of advanced electronics in automobiles. This market has a growing need for miniaturization, better frequency stability, and reduced power consumption as manufacturers keep working on meeting evolving customer needs.- 1.1 Report description

- 1.2 Key market segments

- 1.3 Key benefits to the stakeholders

2: Executive Summary

- 2.1 Quartz Crystal Oscillator- Snapshot

- 2.2 Quartz Crystal Oscillator- Segment Snapshot

- 2.3 Quartz Crystal Oscillator- Competitive Landscape Snapshot

3: Market Overview

- 3.1 Market definition and scope

- 3.2 Key findings

- 3.2.1 Top impacting factors

- 3.2.2 Top investment pockets

- 3.3 Porter’s five forces analysis

- 3.3.1 Low bargaining power of suppliers

- 3.3.2 Low threat of new entrants

- 3.3.3 Low threat of substitutes

- 3.3.4 Low intensity of rivalry

- 3.3.5 Low bargaining power of buyers

- 3.4 Market dynamics

- 3.4.1 Drivers

- 3.4.2 Restraints

- 3.4.3 Opportunities

4: Quartz Crystal Oscillator Market by Type

- 4.1 Overview

- 4.1.1 Market size and forecast

- 4.2 Simple Packaged Crystal Oscillator (Spxo)

- 4.2.1 Key market trends, factors driving growth, and opportunities

- 4.2.2 Market size and forecast, by region

- 4.2.3 Market share analysis by country

- 4.3 Temperature-Compensated Crystal Oscillator (Tcxo)

- 4.3.1 Key market trends, factors driving growth, and opportunities

- 4.3.2 Market size and forecast, by region

- 4.3.3 Market share analysis by country

- 4.4 Voltage-Controlled Crystal Oscillator (Vcxo) Frequency-Controlled Crystal Oscillator (Fcxo)

- 4.4.1 Key market trends, factors driving growth, and opportunities

- 4.4.2 Market size and forecast, by region

- 4.4.3 Market share analysis by country

- 4.5 Oven Controlled Crystal Oscillator (Ocxo)

- 4.5.1 Key market trends, factors driving growth, and opportunities

- 4.5.2 Market size and forecast, by region

- 4.5.3 Market share analysis by country

- 4.6 Others

- 4.6.1 Key market trends, factors driving growth, and opportunities

- 4.6.2 Market size and forecast, by region

- 4.6.3 Market share analysis by country

5: Quartz Crystal Oscillator Market by Application / by End Use

- 5.1 Overview

- 5.1.1 Market size and forecast

- 5.2 Telecom and Networking

- 5.2.1 Key market trends, factors driving growth, and opportunities

- 5.2.2 Market size and forecast, by region

- 5.2.3 Market share analysis by country

- 5.3 Consumer Electronics

- 5.3.1 Key market trends, factors driving growth, and opportunities

- 5.3.2 Market size and forecast, by region

- 5.3.3 Market share analysis by country

- 5.4 Military and Aerospace

- 5.4.1 Key market trends, factors driving growth, and opportunities

- 5.4.2 Market size and forecast, by region

- 5.4.3 Market share analysis by country

- 5.5 Industrial

- 5.5.1 Key market trends, factors driving growth, and opportunities

- 5.5.2 Market size and forecast, by region

- 5.5.3 Market share analysis by country

- 5.6 Automotive

- 5.6.1 Key market trends, factors driving growth, and opportunities

- 5.6.2 Market size and forecast, by region

- 5.6.3 Market share analysis by country

- 5.7 Medical Equipment

- 5.7.1 Key market trends, factors driving growth, and opportunities

- 5.7.2 Market size and forecast, by region

- 5.7.3 Market share analysis by country

- 5.8 Others

- 5.8.1 Key market trends, factors driving growth, and opportunities

- 5.8.2 Market size and forecast, by region

- 5.8.3 Market share analysis by country

6: Competitive Landscape

- 6.1 Overview

- 6.2 Key Winning Strategies

- 6.3 Top 10 Players: Product Mapping

- 6.4 Competitive Analysis Dashboard

- 6.5 Market Competition Heatmap

- 6.6 Leading Player Positions, 2022

7: Company Profiles

- 7.1 Daishinku Corp. (Japan)

- 7.1.1 Company Overview

- 7.1.2 Key Executives

- 7.1.3 Company snapshot

- 7.1.4 Active Business Divisions

- 7.1.5 Product portfolio

- 7.1.6 Business performance

- 7.1.7 Major Strategic Initiatives and Developments

- 7.2 Hosonic Electronic (Taiwan)

- 7.2.1 Company Overview

- 7.2.2 Key Executives

- 7.2.3 Company snapshot

- 7.2.4 Active Business Divisions

- 7.2.5 Product portfolio

- 7.2.6 Business performance

- 7.2.7 Major Strategic Initiatives and Developments

- 7.3 Kyocera Crystal Device (KCD) (Japan)

- 7.3.1 Company Overview

- 7.3.2 Key Executives

- 7.3.3 Company snapshot

- 7.3.4 Active Business Divisions

- 7.3.5 Product portfolio

- 7.3.6 Business performance

- 7.3.7 Major Strategic Initiatives and Developments

- 7.4 Mercury Electronic (Taiwan)

- 7.4.1 Company Overview

- 7.4.2 Key Executives

- 7.4.3 Company snapshot

- 7.4.4 Active Business Divisions

- 7.4.5 Product portfolio

- 7.4.6 Business performance

- 7.4.7 Major Strategic Initiatives and Developments

- 7.5 Miyazaki Epson Corporation (Japan)

- 7.5.1 Company Overview

- 7.5.2 Key Executives

- 7.5.3 Company snapshot

- 7.5.4 Active Business Divisions

- 7.5.5 Product portfolio

- 7.5.6 Business performance

- 7.5.7 Major Strategic Initiatives and Developments

- 7.6 Murata Manufacturing (Japan)

- 7.6.1 Company Overview

- 7.6.2 Key Executives

- 7.6.3 Company snapshot

- 7.6.4 Active Business Divisions

- 7.6.5 Product portfolio

- 7.6.6 Business performance

- 7.6.7 Major Strategic Initiatives and Developments

- 7.7 Nihon Dempa Kogyo (NDK) Co. LTD. (Japan)

- 7.7.1 Company Overview

- 7.7.2 Key Executives

- 7.7.3 Company snapshot

- 7.7.4 Active Business Divisions

- 7.7.5 Product portfolio

- 7.7.6 Business performance

- 7.7.7 Major Strategic Initiatives and Developments

- 7.8 Oscilloquartz SA (Switzerland)

- 7.8.1 Company Overview

- 7.8.2 Key Executives

- 7.8.3 Company snapshot

- 7.8.4 Active Business Divisions

- 7.8.5 Product portfolio

- 7.8.6 Business performance

- 7.8.7 Major Strategic Initiatives and Developments

- 7.9 Rakon Ltd. (New Zealand)

- 7.9.1 Company Overview

- 7.9.2 Key Executives

- 7.9.3 Company snapshot

- 7.9.4 Active Business Divisions

- 7.9.5 Product portfolio

- 7.9.6 Business performance

- 7.9.7 Major Strategic Initiatives and Developments

- 7.10 River Eletec Corp. (Taiwan)

- 7.10.1 Company Overview

- 7.10.2 Key Executives

- 7.10.3 Company snapshot

- 7.10.4 Active Business Divisions

- 7.10.5 Product portfolio

- 7.10.6 Business performance

- 7.10.7 Major Strategic Initiatives and Developments

- 7.11 Siward Crystal Technology (Taiwan)

- 7.11.1 Company Overview

- 7.11.2 Key Executives

- 7.11.3 Company snapshot

- 7.11.4 Active Business Divisions

- 7.11.5 Product portfolio

- 7.11.6 Business performance

- 7.11.7 Major Strategic Initiatives and Developments

- 7.12 Txc Corporation (Taiwan)

- 7.12.1 Company Overview

- 7.12.2 Key Executives

- 7.12.3 Company snapshot

- 7.12.4 Active Business Divisions

- 7.12.5 Product portfolio

- 7.12.6 Business performance

- 7.12.7 Major Strategic Initiatives and Developments

- 7.13 Vectron International (United States)

- 7.13.1 Company Overview

- 7.13.2 Key Executives

- 7.13.3 Company snapshot

- 7.13.4 Active Business Divisions

- 7.13.5 Product portfolio

- 7.13.6 Business performance

- 7.13.7 Major Strategic Initiatives and Developments

8: Analyst Perspective and Conclusion

- 8.1 Concluding Recommendations and Analysis

- 8.2 Strategies for Market Potential

Scope of Report

| Aspects | Details |

|---|---|

By Type |

|

By Application |

|

Report Licenses

Our Team

Frequently Asked Questions (FAQ):

What is the projected market size of Quartz Crystal Oscillator in 2030?

+

-

Which application type is expected to remain the largest segment in the Global Quartz Crystal Oscillator market?

+

-

How big is the Global Quartz Crystal Oscillator market?

+

-

How do regulatory policies impact the Quartz Crystal Oscillator Market?

+

-

What major players in Quartz Crystal Oscillator Market?

+

-

What applications are categorized in the Quartz Crystal Oscillator market study?

+

-

Which product types are examined in the Quartz Crystal Oscillator Market Study?

+

-

Which regions are expected to show the fastest growth in the Quartz Crystal Oscillator market?

+

-

Which application holds the second-highest market share in the Quartz Crystal Oscillator market?

+

-

What are the major growth drivers in the Quartz Crystal Oscillator market?

+

-