Global Pneumatic Conveying System Market Size, Share & Trends Analysis Report, Forecast Period, 2025-2030

Report ID: MS-2412 | Healthcare and Pharma | Last updated: Jan, 2025 | Formats*:

Pneumatic Conveying System Report Highlights

| Report Metrics | Details |

|---|---|

| Forecast period | 2019-2030 |

| Base Year Of Estimation | 2024 |

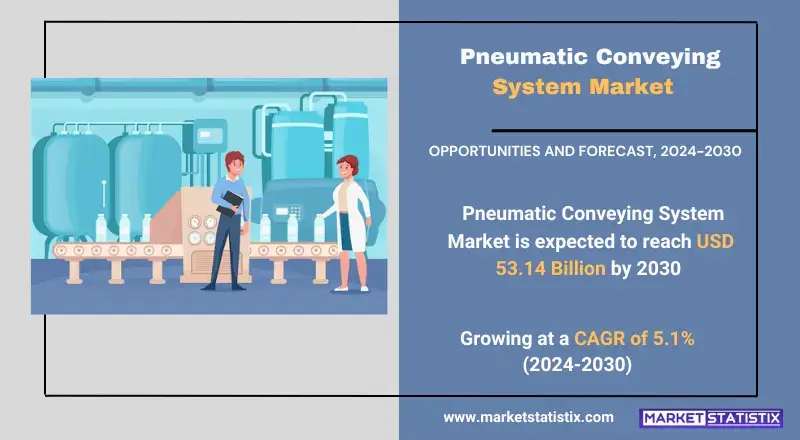

| Growth Rate | CAGR of 5.1% |

| Forecast Value (2030) | USD 53.14 Billion |

| Key Market Players |

|

| By Region |

|

Pneumatic Conveying System Market Trends

The growth of the market is due to the spreading of automation in manufacturing and also in the desire for cleaner and safer solutions in material handling. One of the market trends that deserves to be highlighted is the increasing use of high-tech advantages, such as IoT (Internet of Things)-based pneumatic conveyancing systems, that are able not just to monitor in real time but also to predict maintenance. This combination of smart technologies is improving system performance, decreasing downtime, and making the systems more reliable. Furthermore, there is an increasing interest in energy-efficient and environmentally sound solutions that have resulted in the emergence of more eco-friendly pneumatic conveying systems with low energy and operational costs.Pneumatic Conveying System Market Leading Players

The key players profiled in the report are Indpro Engineering Systems Pvt. Ltd., Hatch, Piab Group, Nol-Tec Systems Inc., Coperion GmbH, Pneumatic Conveying, Inc., Cyclonaire Corporation, Nilfisk Group, Dynamic Air Inc., Flexicon Corporation, Gericke AG, Schenck Process Holding GmbH, Atlas Copco AB, VAC-U-MAXGrowth Accelerators

The market for pneumatic conveying systems is mainly influenced by the growing trend in automation and high-performance material transportation among sectors including food and beverage, pharmaceuticals, chemical, and mining industries. Such systems provide several benefits regarding labour cost reduction, safety, and productivity by automating bulk material transportation. Another important factor is the trend toward environmental sustainability and the environmental safety regulations. Pneumatic conveying systems, particularly those working in an airbed environment, offer a dust-free and clean way to convey the material, which enables the industries to fulfil the stricter environmental and occupational health standards. The continuous diffusion of next-generation technologies, such as energy-saving and intelligent ones, together with the higher and higher demand for personalized solutions, is also driving the demand for pneumatic conveyor systems in multifarious industries.Pneumatic Conveying System Market Segmentation analysis

The Global Pneumatic Conveying System is segmented by Application, and Region. . The Application segment categorizes the market based on its usage such as Food Industry, Cement, Automotive, Ceramic, Rubber and Plastic Industry, Pharmaceuticals, Mining, Others. Geographically, the market is assessed across key Regions like North America (United States, Canada, Mexico), South America (Brazil, Argentina, Chile, Rest of South America), Europe (Germany, France, Italy, United Kingdom, Benelux, Nordics, Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia, Southeast Asia, Rest of Asia-Pacific), MEA (Middle East, Africa) and others, each presenting distinct growth opportunities and challenges influenced by the regions.Competitive Landscape

The competitive environment of the pneumatic conveying system market is marked by the presence of a number of major players, both globally and locally, providing various systems with high functionalities corresponding to various purposes, namely food and beverage, chemicals, pharmaceuticals, mining, and so on. Market leaders are strongly committed to innovation in products, to the production of energy-saving options, and to the use of automation and IoT for better system performance and for monitoring. Companies focus on customization of the conveying system according to the kinds of materials that can be conveyed, the total length of the conveyers, and the processing environments, thereby establishing their position in the market.Challenges In Pneumatic Conveying System Market

The pneumatic conveying system market is subject to some pitfalls, mainly in the form of significant initial investment and operating costs. Such systems, particularly for industrial-scale applications, come at a high acquisition cost for installation, operation, and energy usage. The demand for specific components, e.g., compressors, pipelines, and filters, increases the final cost, which may dissuade the application by small and medium-sized enterprises of the systems. The other concern is the complexity of the system design and maintenance, especially for the industries that work with abrasive or delicate materials. Ensuring proper material flow, avoiding blockages, and maintaining system performance over time require advanced design, regular inspection, and skilled operators. In addition, safety-related problems, including the danger of dust explosions and the use of hazardous materials, necessitate the strict adherence to safety standards and regulations, making the system implementation and operation even more complex. These aspects present a challenge to the industrial application of pneumatic conveying systems.Risks & Prospects in Pneumatic Conveying System Market

The pneumatic conveying systems market offers a number of substantial growth opportunities. The growing need for automation in many industry sectors, but most importantly in food and beverages, pharmaceuticals, and chemical sectors, is pushing towards the adoption of such systems. In addition, the increasing importance of energy efficiency and sustainability today drives the need for more energy-efficient pneumatic conveying systems, thus opening pathways for new technologies and designs. There are significant opportunities in areas of industry where the use of customized pneumatic conveying solutions meets the demands of both safety and regulation for handling hazardous materials.Key Target Audience

The main market target users for the pneumatic conveying system market are chemical, food and beverage, pharmaceutical, and mining industries. Pneumatic conveying systems are commonly in use in the chemical and pharmaceutical industries for transferring powders, granules, and other bulk solids safely without contamination, efficiently, and effectively. Even in the food and beverage industry, in particular, these systems are used to transport ingredients (e.g., flour, sugar, and grains) while keeping things hygienic and preventing food spoilage.,, Moreover, other sectors such as mining and cement production employ pneumatic conveying systems for delivering feed materials like minerals, ores, and cement over long distances in plant facilities. Examples of other target groups are packaging companies, plastic manufacturers, and recycling companies, where such systems are useful in processing different materials such as plastics, metals, and waste material.Merger and acquisition

Recent mergers and acquisitions in the pneumatic conveying system market indicate a strategic move by the industry players to upgrade and increase their market share. In April 2023, an important event happened: Addtech Process Technology purchased Clyde Holding Limited, a UK-based pneumatic conveying system manufacturer. This acquisition is anticipated to strengthen Addtech's process systems business unit by merging Clyde's knowledge and increasing its portfolio in the process and energy market that is increasingly dependent on efficient material handling solutions. As examples, Coperion and Schenck Process are engaged in active expansion of their portfolios through strategic collaborations and technology mapping, which both suggest further consolidation as firms seek to respond to the changing demands of their customers in a market with growing competitive pressures. >Analyst Comment

"Due to its wide and efficient material handling potential for a variety of industries, including food processing, pharmaceuticals, chemicals, and bulk materials applications, the market for pneumatic conveying systems is growing rapidly. Pneumatic conveying systems transfer material using air pressure in pipes, providing benefits including reduced physical manipulation, less risk of contamination, and extension of material transport over great distances or complex paths. The market is stimulated by the rising demand for automation in the industrial processes and the constant desire to take advantage of the efficient but dust-free systems for material transportation."- 1.1 Report description

- 1.2 Key market segments

- 1.3 Key benefits to the stakeholders

2: Executive Summary

- 2.1 Pneumatic Conveying System- Snapshot

- 2.2 Pneumatic Conveying System- Segment Snapshot

- 2.3 Pneumatic Conveying System- Competitive Landscape Snapshot

3: Market Overview

- 3.1 Market definition and scope

- 3.2 Key findings

- 3.2.1 Top impacting factors

- 3.2.2 Top investment pockets

- 3.3 Porter’s five forces analysis

- 3.3.1 Low bargaining power of suppliers

- 3.3.2 Low threat of new entrants

- 3.3.3 Low threat of substitutes

- 3.3.4 Low intensity of rivalry

- 3.3.5 Low bargaining power of buyers

- 3.4 Market dynamics

- 3.4.1 Drivers

- 3.4.2 Restraints

- 3.4.3 Opportunities

4: Pneumatic Conveying System Market by Application / by End Use

- 4.1 Overview

- 4.1.1 Market size and forecast

- 4.2 Automotive

- 4.2.1 Key market trends, factors driving growth, and opportunities

- 4.2.2 Market size and forecast, by region

- 4.2.3 Market share analysis by country

- 4.3 Cement

- 4.3.1 Key market trends, factors driving growth, and opportunities

- 4.3.2 Market size and forecast, by region

- 4.3.3 Market share analysis by country

- 4.4 Ceramic

- 4.4.1 Key market trends, factors driving growth, and opportunities

- 4.4.2 Market size and forecast, by region

- 4.4.3 Market share analysis by country

- 4.5 Food Industry

- 4.5.1 Key market trends, factors driving growth, and opportunities

- 4.5.2 Market size and forecast, by region

- 4.5.3 Market share analysis by country

- 4.6 Mining

- 4.6.1 Key market trends, factors driving growth, and opportunities

- 4.6.2 Market size and forecast, by region

- 4.6.3 Market share analysis by country

- 4.7 Pharmaceuticals

- 4.7.1 Key market trends, factors driving growth, and opportunities

- 4.7.2 Market size and forecast, by region

- 4.7.3 Market share analysis by country

- 4.8 Rubber and Plastic Industry

- 4.8.1 Key market trends, factors driving growth, and opportunities

- 4.8.2 Market size and forecast, by region

- 4.8.3 Market share analysis by country

- 4.9 Others

- 4.9.1 Key market trends, factors driving growth, and opportunities

- 4.9.2 Market size and forecast, by region

- 4.9.3 Market share analysis by country

5: Pneumatic Conveying System Market by Technology

- 5.1 Overview

- 5.1.1 Market size and forecast

- 5.2 Combination Systems

- 5.2.1 Key market trends, factors driving growth, and opportunities

- 5.2.2 Market size and forecast, by region

- 5.2.3 Market share analysis by country

- 5.3 Positive Pressure Systems

- 5.3.1 Key market trends, factors driving growth, and opportunities

- 5.3.2 Market size and forecast, by region

- 5.3.3 Market share analysis by country

- 5.4 Vacuum Systems

- 5.4.1 Key market trends, factors driving growth, and opportunities

- 5.4.2 Market size and forecast, by region

- 5.4.3 Market share analysis by country

6: Pneumatic Conveying System Market by Operation

- 6.1 Overview

- 6.1.1 Market size and forecast

- 6.2 Dense Phase Conveying

- 6.2.1 Key market trends, factors driving growth, and opportunities

- 6.2.2 Market size and forecast, by region

- 6.2.3 Market share analysis by country

- 6.3 Dilute Phase Conveying

- 6.3.1 Key market trends, factors driving growth, and opportunities

- 6.3.2 Market size and forecast, by region

- 6.3.3 Market share analysis by country

7: Pneumatic Conveying System Market by Region

- 7.1 Overview

- 7.1.1 Market size and forecast By Region

- 7.2 North America

- 7.2.1 Key trends and opportunities

- 7.2.2 Market size and forecast, by Type

- 7.2.3 Market size and forecast, by Application

- 7.2.4 Market size and forecast, by country

- 7.2.4.1 United States

- 7.2.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.1.2 Market size and forecast, by Type

- 7.2.4.1.3 Market size and forecast, by Application

- 7.2.4.2 Canada

- 7.2.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.2.2 Market size and forecast, by Type

- 7.2.4.2.3 Market size and forecast, by Application

- 7.2.4.3 Mexico

- 7.2.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.3.2 Market size and forecast, by Type

- 7.2.4.3.3 Market size and forecast, by Application

- 7.2.4.1 United States

- 7.3 South America

- 7.3.1 Key trends and opportunities

- 7.3.2 Market size and forecast, by Type

- 7.3.3 Market size and forecast, by Application

- 7.3.4 Market size and forecast, by country

- 7.3.4.1 Brazil

- 7.3.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.1.2 Market size and forecast, by Type

- 7.3.4.1.3 Market size and forecast, by Application

- 7.3.4.2 Argentina

- 7.3.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.2.2 Market size and forecast, by Type

- 7.3.4.2.3 Market size and forecast, by Application

- 7.3.4.3 Chile

- 7.3.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.3.2 Market size and forecast, by Type

- 7.3.4.3.3 Market size and forecast, by Application

- 7.3.4.4 Rest of South America

- 7.3.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.4.2 Market size and forecast, by Type

- 7.3.4.4.3 Market size and forecast, by Application

- 7.3.4.1 Brazil

- 7.4 Europe

- 7.4.1 Key trends and opportunities

- 7.4.2 Market size and forecast, by Type

- 7.4.3 Market size and forecast, by Application

- 7.4.4 Market size and forecast, by country

- 7.4.4.1 Germany

- 7.4.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.1.2 Market size and forecast, by Type

- 7.4.4.1.3 Market size and forecast, by Application

- 7.4.4.2 France

- 7.4.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.2.2 Market size and forecast, by Type

- 7.4.4.2.3 Market size and forecast, by Application

- 7.4.4.3 Italy

- 7.4.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.3.2 Market size and forecast, by Type

- 7.4.4.3.3 Market size and forecast, by Application

- 7.4.4.4 United Kingdom

- 7.4.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.4.2 Market size and forecast, by Type

- 7.4.4.4.3 Market size and forecast, by Application

- 7.4.4.5 Benelux

- 7.4.4.5.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.5.2 Market size and forecast, by Type

- 7.4.4.5.3 Market size and forecast, by Application

- 7.4.4.6 Nordics

- 7.4.4.6.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.6.2 Market size and forecast, by Type

- 7.4.4.6.3 Market size and forecast, by Application

- 7.4.4.7 Rest of Europe

- 7.4.4.7.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.7.2 Market size and forecast, by Type

- 7.4.4.7.3 Market size and forecast, by Application

- 7.4.4.1 Germany

- 7.5 Asia Pacific

- 7.5.1 Key trends and opportunities

- 7.5.2 Market size and forecast, by Type

- 7.5.3 Market size and forecast, by Application

- 7.5.4 Market size and forecast, by country

- 7.5.4.1 China

- 7.5.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.1.2 Market size and forecast, by Type

- 7.5.4.1.3 Market size and forecast, by Application

- 7.5.4.2 Japan

- 7.5.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.2.2 Market size and forecast, by Type

- 7.5.4.2.3 Market size and forecast, by Application

- 7.5.4.3 India

- 7.5.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.3.2 Market size and forecast, by Type

- 7.5.4.3.3 Market size and forecast, by Application

- 7.5.4.4 South Korea

- 7.5.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.4.2 Market size and forecast, by Type

- 7.5.4.4.3 Market size and forecast, by Application

- 7.5.4.5 Australia

- 7.5.4.5.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.5.2 Market size and forecast, by Type

- 7.5.4.5.3 Market size and forecast, by Application

- 7.5.4.6 Southeast Asia

- 7.5.4.6.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.6.2 Market size and forecast, by Type

- 7.5.4.6.3 Market size and forecast, by Application

- 7.5.4.7 Rest of Asia-Pacific

- 7.5.4.7.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.7.2 Market size and forecast, by Type

- 7.5.4.7.3 Market size and forecast, by Application

- 7.5.4.1 China

- 7.6 MEA

- 7.6.1 Key trends and opportunities

- 7.6.2 Market size and forecast, by Type

- 7.6.3 Market size and forecast, by Application

- 7.6.4 Market size and forecast, by country

- 7.6.4.1 Middle East

- 7.6.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.6.4.1.2 Market size and forecast, by Type

- 7.6.4.1.3 Market size and forecast, by Application

- 7.6.4.2 Africa

- 7.6.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.6.4.2.2 Market size and forecast, by Type

- 7.6.4.2.3 Market size and forecast, by Application

- 7.6.4.1 Middle East

- 8.1 Overview

- 8.2 Key Winning Strategies

- 8.3 Top 10 Players: Product Mapping

- 8.4 Competitive Analysis Dashboard

- 8.5 Market Competition Heatmap

- 8.6 Leading Player Positions, 2022

9: Company Profiles

- 9.1 Atlas Copco AB

- 9.1.1 Company Overview

- 9.1.2 Key Executives

- 9.1.3 Company snapshot

- 9.1.4 Active Business Divisions

- 9.1.5 Product portfolio

- 9.1.6 Business performance

- 9.1.7 Major Strategic Initiatives and Developments

- 9.2 Coperion GmbH

- 9.2.1 Company Overview

- 9.2.2 Key Executives

- 9.2.3 Company snapshot

- 9.2.4 Active Business Divisions

- 9.2.5 Product portfolio

- 9.2.6 Business performance

- 9.2.7 Major Strategic Initiatives and Developments

- 9.3 Cyclonaire Corporation

- 9.3.1 Company Overview

- 9.3.2 Key Executives

- 9.3.3 Company snapshot

- 9.3.4 Active Business Divisions

- 9.3.5 Product portfolio

- 9.3.6 Business performance

- 9.3.7 Major Strategic Initiatives and Developments

- 9.4 Dynamic Air Inc.

- 9.4.1 Company Overview

- 9.4.2 Key Executives

- 9.4.3 Company snapshot

- 9.4.4 Active Business Divisions

- 9.4.5 Product portfolio

- 9.4.6 Business performance

- 9.4.7 Major Strategic Initiatives and Developments

- 9.5 Flexicon Corporation

- 9.5.1 Company Overview

- 9.5.2 Key Executives

- 9.5.3 Company snapshot

- 9.5.4 Active Business Divisions

- 9.5.5 Product portfolio

- 9.5.6 Business performance

- 9.5.7 Major Strategic Initiatives and Developments

- 9.6 Gericke AG

- 9.6.1 Company Overview

- 9.6.2 Key Executives

- 9.6.3 Company snapshot

- 9.6.4 Active Business Divisions

- 9.6.5 Product portfolio

- 9.6.6 Business performance

- 9.6.7 Major Strategic Initiatives and Developments

- 9.7 Hatch

- 9.7.1 Company Overview

- 9.7.2 Key Executives

- 9.7.3 Company snapshot

- 9.7.4 Active Business Divisions

- 9.7.5 Product portfolio

- 9.7.6 Business performance

- 9.7.7 Major Strategic Initiatives and Developments

- 9.8 Indpro Engineering Systems Pvt. Ltd.

- 9.8.1 Company Overview

- 9.8.2 Key Executives

- 9.8.3 Company snapshot

- 9.8.4 Active Business Divisions

- 9.8.5 Product portfolio

- 9.8.6 Business performance

- 9.8.7 Major Strategic Initiatives and Developments

- 9.9 Nilfisk Group

- 9.9.1 Company Overview

- 9.9.2 Key Executives

- 9.9.3 Company snapshot

- 9.9.4 Active Business Divisions

- 9.9.5 Product portfolio

- 9.9.6 Business performance

- 9.9.7 Major Strategic Initiatives and Developments

- 9.10 Nol-Tec Systems Inc.

- 9.10.1 Company Overview

- 9.10.2 Key Executives

- 9.10.3 Company snapshot

- 9.10.4 Active Business Divisions

- 9.10.5 Product portfolio

- 9.10.6 Business performance

- 9.10.7 Major Strategic Initiatives and Developments

- 9.11 Piab Group

- 9.11.1 Company Overview

- 9.11.2 Key Executives

- 9.11.3 Company snapshot

- 9.11.4 Active Business Divisions

- 9.11.5 Product portfolio

- 9.11.6 Business performance

- 9.11.7 Major Strategic Initiatives and Developments

- 9.12 Pneumatic Conveying

- 9.12.1 Company Overview

- 9.12.2 Key Executives

- 9.12.3 Company snapshot

- 9.12.4 Active Business Divisions

- 9.12.5 Product portfolio

- 9.12.6 Business performance

- 9.12.7 Major Strategic Initiatives and Developments

- 9.13 Inc.

- 9.13.1 Company Overview

- 9.13.2 Key Executives

- 9.13.3 Company snapshot

- 9.13.4 Active Business Divisions

- 9.13.5 Product portfolio

- 9.13.6 Business performance

- 9.13.7 Major Strategic Initiatives and Developments

- 9.14 Schenck Process Holding GmbH

- 9.14.1 Company Overview

- 9.14.2 Key Executives

- 9.14.3 Company snapshot

- 9.14.4 Active Business Divisions

- 9.14.5 Product portfolio

- 9.14.6 Business performance

- 9.14.7 Major Strategic Initiatives and Developments

- 9.15 VAC-U-MAX

- 9.15.1 Company Overview

- 9.15.2 Key Executives

- 9.15.3 Company snapshot

- 9.15.4 Active Business Divisions

- 9.15.5 Product portfolio

- 9.15.6 Business performance

- 9.15.7 Major Strategic Initiatives and Developments

10: Analyst Perspective and Conclusion

- 10.1 Concluding Recommendations and Analysis

- 10.2 Strategies for Market Potential

Scope of Report

| Aspects | Details |

|---|---|

By Application |

|

By Technology |

|

By Operation |

|

Report Licenses

Our Team

Frequently Asked Questions (FAQ):

What is the estimated market size of Pneumatic Conveying System in 2030?

+

-

What is the growth rate of Pneumatic Conveying System Market?

+

-

What are the latest trends influencing the Pneumatic Conveying System Market?

+

-

Who are the key players in the Pneumatic Conveying System Market?

+

-

How is the Pneumatic Conveying System } industry progressing in scaling its end-use implementations?

+

-

What product types are analyzed in the Pneumatic Conveying System Market Study?

+

-

What geographic breakdown is available in Global Pneumatic Conveying System Market Study?

+

-

Which region holds the second position by market share in the Pneumatic Conveying System market?

+

-

Which region holds the highest growth rate in the Pneumatic Conveying System market?

+

-

How are the key players in the Pneumatic Conveying System market targeting growth in the future?

+

-