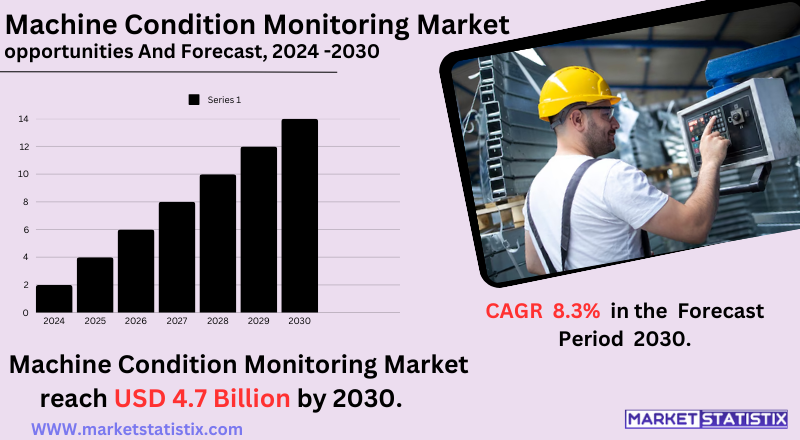

Global Machine condition monitoring Market Size, Share & Trends Analysis Report, Forecast Period, 2024-2030

Report ID: MS-2542 | Manufacturing and Construction | Last updated: Feb, 2025 | Formats*:

Machine condition monitoring Report Highlights

| Report Metrics | Details |

|---|---|

| Forecast period | 2019-2030 |

| Base Year Of Estimation | 2024 |

| Growth Rate | CAGR of 8.3% |

| Forecast Value (2030) | USD 4.7 Billion |

| By Product Type | Motors, Bearings, Valves, Couplings, Gearbox, Turbines, Compressors, Others |

| Key Market Players |

|

| By Region |

|

Machine condition monitoring Market Trends

The MCM market is globally pushed toward predictive maintenance because of the increasing instances of data from connected devices and advancing analytics. The real-time data and information coming from sensors fused with AI and machine learning algorithms enhance the prediction accuracy of equipment failings, thus allowing maintenance to take proactive measures to reduce downtime. This transfer focuses away from reactive or preventive maintenance toward a more proactive and efficient approach. Another significant trend of the MCM market is cloud-based solutions and remote monitoring. Cloud solutions lead to pooled, centralised data storage, analysis, and access, giving the maintenance team the possibility to monitor equipment performance from any place. This is especially beneficial where assets are geographically dispersed. The growing adoption of industrial IoT systems and wireless sensor networks is further facilitating remote monitoring and data collection, making MCM an accessible and cost-effective solution.Machine condition monitoring Market Leading Players

The key players profiled in the report are SKF, ALS, Honeywell International Inc., Emerson Electric Co., Schaeffler AG, Rockwell Automation, Inc., Megget PLC, Parker Hannifin, General Electric, NATIONAL INSTRUMENTS CORPGrowth Accelerators

The increasing adoption of predictive maintenance strategies by industries like manufacturing, oil and gas, power generation, automotive, and others drives the machine condition monitoring market. Real-time monitoring solutions are preferred by companies to minimise unplanned downtime, increase equipment life, and improve operational efficiency. Enhanced demand for advanced condition monitoring systems is due to the Industrial Internet of Things (IIoT) and AI-based analytics, which enable automated fault detection and predictive insights. Stringent regulations on workplace safety and equipment maintenance further encourage market growth, with industries being forced to adopt reliable monitoring solutions. The steady growth has also been further enhanced by the increased demand for wireless and remote monitoring technologies propelled by life and Industry 4.0 and smart manufacturing trends. Investments continue to rise in condition monitoring tools, including vibration analysis, infrared thermography, and ultrasonic detection technologies, as industries embrace data-driven decision-making, positioning them for future growth.Machine condition monitoring Market Segmentation analysis

The Global Machine condition monitoring is segmented by Type, Application, and Region. By Type, the market is divided into Distributed Motors, Bearings, Valves, Couplings, Gearbox, Turbines, Compressors, Others . The Application segment categorizes the market based on its usage such as Bushings & Hubs, Motor Control, Control Cabinet Monitoring, Conveyors, Storage Rooms, Material Handling, Paper Presses, Sprockets, Pump Systems, Lubricant Level Monitoring on CNC Machines, Others. Geographically, the market is assessed across key Regions like North America(United States, Canada, Mexico), South America(Brazil, Argentina, Chile, Rest of South America), Europe(Germany, France, Italy, United Kingdom, Benelux, Nordics, Rest of Europe), Asia Pacific(China, Japan, India, South Korea, Australia, Southeast Asia, Rest of Asia-Pacific), MEA(Middle East, Africa) and others, each presenting distinct growth opportunities and challenges influenced by the regions.Competitive Landscape

The Machine Condition Monitoring (MCM) market displays a limited degree of competitiveness and is home to a number of established as well as emerging companies competing for market share. The key players in this pool are the large industrial conglomerates such as Emerson Electric, General Electric, SKF, and specialised MCM solution providers. The competition is predicated on factors such as technology leadership, product portfolio breadth, service capabilities, and pricing. The companies continue to invest a lot into research and development to provide more advanced and integrated MCM solutions, including AI-based analytic capabilities and solution delivery via cloud platforms.Challenges In Machine condition monitoring Market

The machine condition monitoring business is plagued by several barriers and threats to its growth and adoption. An important concern is the high amount of initial investment that is required to set up these systems—for sensors, data acquisition devices, and specific software. The other issue is the operational costs; once the systems are set up, there are costs such as data analysis and maintenance that gradually rise over time to become a burden on SMEs in adopting such technologies. Another hurdle is the unavailability of well-trained personnel in data analytics and condition monitoring output interpretation. The success of these systems is closely tied to the analysis of the data; correct analysis leads to maintenance predictions and prevention of unplanned failures of equipment. Without these people, companies may end up being unable to fully realise condition monitoring solutions, resulting in inefficient maintenance scheduling and possible disruption of operations.Risks & Prospects in Machine condition monitoring Market

The advent of Industry 4.0 technologies progresses the Machine Condition Monitoring (MCM) business undeniably to greater heights. The advent of artificial intelligence and machine learning, along with IoT, in MCM has approved more complicated predictive maintenance methods, which in turn favour solution providers and the chances of more advanced analytics with insights. Another growth opportunity for the market finds ground due to developments concerning remote and cloud MCM solutions. North America and Europe have taken the lead among other regions in MCM because of the fairly developed industries, which emphasise automation and efficiency. Asia Pacific has been predicted to have the highest rate of growth in the future due to rapidly industrialising nations, huge capital investments in infrastructure development, and increasing awareness of predictive maintenance benefits. Significant growth is expected in the Middle East and Latin America as a result of their increased investment in constructing industrial sector frameworks.Key Target Audience

Maintenance professionals and asset managers from different industries are considered to be the main target audiences for the MCM market. These are the people who ensure the reliability and uptime of critical machinery and equipment. They depend on MCM systems to provide insights into equipment health, predict possible failures, and optimise maintenance schedules. This target audience covers many different industry sectors, such as manufacturing plants, power generation facilities, transportation companies, and oil and gas operations.,, Besides the maintenance personnel, the MCM market also pursues plant operations managers and executives concerned with plant-wide efficiency, cost-cutting, and safety. MCM systems of monitoring provide data-driven insights into equipment performance that allow these individuals to direct resources to allocation, production planning, and capital investment. In effect, MCM benefits cascade from operational efficiency down to organisational and financial profitability.Merger and acquisition

One major trend characterised by mergers and acquisitions is taking place in the machine condition monitoring market, whereby the major players effectively enhance their respective portfolios and market presence. Emerson Electric Co. acquired the National Instruments Corporation in October 2023 for $8.2 billion to enhance machine condition monitoring solutions. Siemens integrated AI-powered solutions for the performance of industrial machinery into its portfolio by acquiring Senseye in June 2022. The smaller companies also participate in acquisitions and mergers to foster innovation and growth. SPM Instrument AB strengthened its presence in Germany and enhanced customer service when it acquired Status-Pro Maschinenmesstechnik GmbH in June 2024. I-Care also acquired the predictive maintenance product line of Sensirion AG in July 2024 to build its presence in Germany and solidify its global leadership. Such strategic moves help companies incorporate advanced technologies like AI and IoT, strengthen their market position, and deliver a wider array of condition-monitoring solutions. >Analyst Comment

The growth of the Machine Condition Monitoring (MCM) market is driven by the increasing awareness regarding the advantages of predictive maintenance and the rapid advent of industry 4.0. It cuts through all the manufacturing sectors where MCM solutions equipment is being adopted to reduce downtime, optimise maintenance schedules, and enhance the overall efficiency of operations. It is supported by growing cost-effective sensors, increasing cloud computing and IoT technology adoption, and improvements in data analytics. On the other hand, the shift is also towards more advanced MCM systems that embed artificial intelligence and machine learning. Along with digitising and automating the industries, it is presumed that the MCM market would maintain its rapid growth in the next few years.- 1.1 Report description

- 1.2 Key market segments

- 1.3 Key benefits to the stakeholders

2: Executive Summary

- 2.1 Machine condition monitoring- Snapshot

- 2.2 Machine condition monitoring- Segment Snapshot

- 2.3 Machine condition monitoring- Competitive Landscape Snapshot

3: Market Overview

- 3.1 Market definition and scope

- 3.2 Key findings

- 3.2.1 Top impacting factors

- 3.2.2 Top investment pockets

- 3.3 Porter’s five forces analysis

- 3.3.1 Low bargaining power of suppliers

- 3.3.2 Low threat of new entrants

- 3.3.3 Low threat of substitutes

- 3.3.4 Low intensity of rivalry

- 3.3.5 Low bargaining power of buyers

- 3.4 Market dynamics

- 3.4.1 Drivers

- 3.4.2 Restraints

- 3.4.3 Opportunities

4: Machine condition monitoring Market by Type

- 4.1 Overview

- 4.1.1 Market size and forecast

- 4.2 Valves

- 4.2.1 Key market trends, factors driving growth, and opportunities

- 4.2.2 Market size and forecast, by region

- 4.2.3 Market share analysis by country

- 4.3 Compressors

- 4.3.1 Key market trends, factors driving growth, and opportunities

- 4.3.2 Market size and forecast, by region

- 4.3.3 Market share analysis by country

- 4.4 Turbines

- 4.4.1 Key market trends, factors driving growth, and opportunities

- 4.4.2 Market size and forecast, by region

- 4.4.3 Market share analysis by country

- 4.5 Gearbox

- 4.5.1 Key market trends, factors driving growth, and opportunities

- 4.5.2 Market size and forecast, by region

- 4.5.3 Market share analysis by country

- 4.6 Motors

- 4.6.1 Key market trends, factors driving growth, and opportunities

- 4.6.2 Market size and forecast, by region

- 4.6.3 Market share analysis by country

- 4.7 Bearings

- 4.7.1 Key market trends, factors driving growth, and opportunities

- 4.7.2 Market size and forecast, by region

- 4.7.3 Market share analysis by country

- 4.8 Couplings

- 4.8.1 Key market trends, factors driving growth, and opportunities

- 4.8.2 Market size and forecast, by region

- 4.8.3 Market share analysis by country

- 4.9 Others

- 4.9.1 Key market trends, factors driving growth, and opportunities

- 4.9.2 Market size and forecast, by region

- 4.9.3 Market share analysis by country

5: Machine condition monitoring Market by Application / by End Use

- 5.1 Overview

- 5.1.1 Market size and forecast

- 5.2 Material Handling

- 5.2.1 Key market trends, factors driving growth, and opportunities

- 5.2.2 Market size and forecast, by region

- 5.2.3 Market share analysis by country

- 5.3 Conveyors

- 5.3.1 Key market trends, factors driving growth, and opportunities

- 5.3.2 Market size and forecast, by region

- 5.3.3 Market share analysis by country

- 5.4 Pump Systems

- 5.4.1 Key market trends, factors driving growth, and opportunities

- 5.4.2 Market size and forecast, by region

- 5.4.3 Market share analysis by country

- 5.5 Sprockets

- 5.5.1 Key market trends, factors driving growth, and opportunities

- 5.5.2 Market size and forecast, by region

- 5.5.3 Market share analysis by country

- 5.6 Bushings & Hubs

- 5.6.1 Key market trends, factors driving growth, and opportunities

- 5.6.2 Market size and forecast, by region

- 5.6.3 Market share analysis by country

- 5.7 Control Cabinet Monitoring

- 5.7.1 Key market trends, factors driving growth, and opportunities

- 5.7.2 Market size and forecast, by region

- 5.7.3 Market share analysis by country

- 5.8 Paper Presses

- 5.8.1 Key market trends, factors driving growth, and opportunities

- 5.8.2 Market size and forecast, by region

- 5.8.3 Market share analysis by country

- 5.9 Storage Rooms

- 5.9.1 Key market trends, factors driving growth, and opportunities

- 5.9.2 Market size and forecast, by region

- 5.9.3 Market share analysis by country

- 5.10 Motor Control

- 5.10.1 Key market trends, factors driving growth, and opportunities

- 5.10.2 Market size and forecast, by region

- 5.10.3 Market share analysis by country

- 5.11 Lubricant Level Monitoring on CNC Machines

- 5.11.1 Key market trends, factors driving growth, and opportunities

- 5.11.2 Market size and forecast, by region

- 5.11.3 Market share analysis by country

- 5.12 Others

- 5.12.1 Key market trends, factors driving growth, and opportunities

- 5.12.2 Market size and forecast, by region

- 5.12.3 Market share analysis by country

6: Machine condition monitoring Market by Architecture

- 6.1 Overview

- 6.1.1 Market size and forecast

- 6.2 Public Cloud

- 6.2.1 Key market trends, factors driving growth, and opportunities

- 6.2.2 Market size and forecast, by region

- 6.2.3 Market share analysis by country

- 6.3 Edge Platform

- 6.3.1 Key market trends, factors driving growth, and opportunities

- 6.3.2 Market size and forecast, by region

- 6.3.3 Market share analysis by country

- 6.4 Hybrid Cloud

- 6.4.1 Key market trends, factors driving growth, and opportunities

- 6.4.2 Market size and forecast, by region

- 6.4.3 Market share analysis by country

7: Machine condition monitoring Market by Region

- 7.1 Overview

- 7.1.1 Market size and forecast By Region

- 7.2 North America

- 7.2.1 Key trends and opportunities

- 7.2.2 Market size and forecast, by Type

- 7.2.3 Market size and forecast, by Application

- 7.2.4 Market size and forecast, by country

- 7.2.4.1 United States

- 7.2.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.1.2 Market size and forecast, by Type

- 7.2.4.1.3 Market size and forecast, by Application

- 7.2.4.2 Canada

- 7.2.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.2.2 Market size and forecast, by Type

- 7.2.4.2.3 Market size and forecast, by Application

- 7.2.4.3 Mexico

- 7.2.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.2.4.3.2 Market size and forecast, by Type

- 7.2.4.3.3 Market size and forecast, by Application

- 7.2.4.1 United States

- 7.3 South America

- 7.3.1 Key trends and opportunities

- 7.3.2 Market size and forecast, by Type

- 7.3.3 Market size and forecast, by Application

- 7.3.4 Market size and forecast, by country

- 7.3.4.1 Brazil

- 7.3.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.1.2 Market size and forecast, by Type

- 7.3.4.1.3 Market size and forecast, by Application

- 7.3.4.2 Argentina

- 7.3.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.2.2 Market size and forecast, by Type

- 7.3.4.2.3 Market size and forecast, by Application

- 7.3.4.3 Chile

- 7.3.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.3.2 Market size and forecast, by Type

- 7.3.4.3.3 Market size and forecast, by Application

- 7.3.4.4 Rest of South America

- 7.3.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.3.4.4.2 Market size and forecast, by Type

- 7.3.4.4.3 Market size and forecast, by Application

- 7.3.4.1 Brazil

- 7.4 Europe

- 7.4.1 Key trends and opportunities

- 7.4.2 Market size and forecast, by Type

- 7.4.3 Market size and forecast, by Application

- 7.4.4 Market size and forecast, by country

- 7.4.4.1 Germany

- 7.4.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.1.2 Market size and forecast, by Type

- 7.4.4.1.3 Market size and forecast, by Application

- 7.4.4.2 France

- 7.4.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.2.2 Market size and forecast, by Type

- 7.4.4.2.3 Market size and forecast, by Application

- 7.4.4.3 Italy

- 7.4.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.3.2 Market size and forecast, by Type

- 7.4.4.3.3 Market size and forecast, by Application

- 7.4.4.4 United Kingdom

- 7.4.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.4.2 Market size and forecast, by Type

- 7.4.4.4.3 Market size and forecast, by Application

- 7.4.4.5 Benelux

- 7.4.4.5.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.5.2 Market size and forecast, by Type

- 7.4.4.5.3 Market size and forecast, by Application

- 7.4.4.6 Nordics

- 7.4.4.6.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.6.2 Market size and forecast, by Type

- 7.4.4.6.3 Market size and forecast, by Application

- 7.4.4.7 Rest of Europe

- 7.4.4.7.1 Key market trends, factors driving growth, and opportunities

- 7.4.4.7.2 Market size and forecast, by Type

- 7.4.4.7.3 Market size and forecast, by Application

- 7.4.4.1 Germany

- 7.5 Asia Pacific

- 7.5.1 Key trends and opportunities

- 7.5.2 Market size and forecast, by Type

- 7.5.3 Market size and forecast, by Application

- 7.5.4 Market size and forecast, by country

- 7.5.4.1 China

- 7.5.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.1.2 Market size and forecast, by Type

- 7.5.4.1.3 Market size and forecast, by Application

- 7.5.4.2 Japan

- 7.5.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.2.2 Market size and forecast, by Type

- 7.5.4.2.3 Market size and forecast, by Application

- 7.5.4.3 India

- 7.5.4.3.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.3.2 Market size and forecast, by Type

- 7.5.4.3.3 Market size and forecast, by Application

- 7.5.4.4 South Korea

- 7.5.4.4.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.4.2 Market size and forecast, by Type

- 7.5.4.4.3 Market size and forecast, by Application

- 7.5.4.5 Australia

- 7.5.4.5.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.5.2 Market size and forecast, by Type

- 7.5.4.5.3 Market size and forecast, by Application

- 7.5.4.6 Southeast Asia

- 7.5.4.6.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.6.2 Market size and forecast, by Type

- 7.5.4.6.3 Market size and forecast, by Application

- 7.5.4.7 Rest of Asia-Pacific

- 7.5.4.7.1 Key market trends, factors driving growth, and opportunities

- 7.5.4.7.2 Market size and forecast, by Type

- 7.5.4.7.3 Market size and forecast, by Application

- 7.5.4.1 China

- 7.6 MEA

- 7.6.1 Key trends and opportunities

- 7.6.2 Market size and forecast, by Type

- 7.6.3 Market size and forecast, by Application

- 7.6.4 Market size and forecast, by country

- 7.6.4.1 Middle East

- 7.6.4.1.1 Key market trends, factors driving growth, and opportunities

- 7.6.4.1.2 Market size and forecast, by Type

- 7.6.4.1.3 Market size and forecast, by Application

- 7.6.4.2 Africa

- 7.6.4.2.1 Key market trends, factors driving growth, and opportunities

- 7.6.4.2.2 Market size and forecast, by Type

- 7.6.4.2.3 Market size and forecast, by Application

- 7.6.4.1 Middle East

- 8.1 Overview

- 8.2 Key Winning Strategies

- 8.3 Top 10 Players: Product Mapping

- 8.4 Competitive Analysis Dashboard

- 8.5 Market Competition Heatmap

- 8.6 Leading Player Positions, 2022

9: Company Profiles

- 9.1 ALS

- 9.1.1 Company Overview

- 9.1.2 Key Executives

- 9.1.3 Company snapshot

- 9.1.4 Active Business Divisions

- 9.1.5 Product portfolio

- 9.1.6 Business performance

- 9.1.7 Major Strategic Initiatives and Developments

- 9.2 Emerson Electric Co.

- 9.2.1 Company Overview

- 9.2.2 Key Executives

- 9.2.3 Company snapshot

- 9.2.4 Active Business Divisions

- 9.2.5 Product portfolio

- 9.2.6 Business performance

- 9.2.7 Major Strategic Initiatives and Developments

- 9.3 General Electric

- 9.3.1 Company Overview

- 9.3.2 Key Executives

- 9.3.3 Company snapshot

- 9.3.4 Active Business Divisions

- 9.3.5 Product portfolio

- 9.3.6 Business performance

- 9.3.7 Major Strategic Initiatives and Developments

- 9.4 Parker Hannifin

- 9.4.1 Company Overview

- 9.4.2 Key Executives

- 9.4.3 Company snapshot

- 9.4.4 Active Business Divisions

- 9.4.5 Product portfolio

- 9.4.6 Business performance

- 9.4.7 Major Strategic Initiatives and Developments

- 9.5 Rockwell Automation

- 9.5.1 Company Overview

- 9.5.2 Key Executives

- 9.5.3 Company snapshot

- 9.5.4 Active Business Divisions

- 9.5.5 Product portfolio

- 9.5.6 Business performance

- 9.5.7 Major Strategic Initiatives and Developments

- 9.6 Inc.

- 9.6.1 Company Overview

- 9.6.2 Key Executives

- 9.6.3 Company snapshot

- 9.6.4 Active Business Divisions

- 9.6.5 Product portfolio

- 9.6.6 Business performance

- 9.6.7 Major Strategic Initiatives and Developments

- 9.7 SKF

- 9.7.1 Company Overview

- 9.7.2 Key Executives

- 9.7.3 Company snapshot

- 9.7.4 Active Business Divisions

- 9.7.5 Product portfolio

- 9.7.6 Business performance

- 9.7.7 Major Strategic Initiatives and Developments

- 9.8 Schaeffler AG

- 9.8.1 Company Overview

- 9.8.2 Key Executives

- 9.8.3 Company snapshot

- 9.8.4 Active Business Divisions

- 9.8.5 Product portfolio

- 9.8.6 Business performance

- 9.8.7 Major Strategic Initiatives and Developments

- 9.9 Honeywell International Inc.

- 9.9.1 Company Overview

- 9.9.2 Key Executives

- 9.9.3 Company snapshot

- 9.9.4 Active Business Divisions

- 9.9.5 Product portfolio

- 9.9.6 Business performance

- 9.9.7 Major Strategic Initiatives and Developments

- 9.10 Megget PLC

- 9.10.1 Company Overview

- 9.10.2 Key Executives

- 9.10.3 Company snapshot

- 9.10.4 Active Business Divisions

- 9.10.5 Product portfolio

- 9.10.6 Business performance

- 9.10.7 Major Strategic Initiatives and Developments

- 9.11 NATIONAL INSTRUMENTS CORP

- 9.11.1 Company Overview

- 9.11.2 Key Executives

- 9.11.3 Company snapshot

- 9.11.4 Active Business Divisions

- 9.11.5 Product portfolio

- 9.11.6 Business performance

- 9.11.7 Major Strategic Initiatives and Developments

10: Analyst Perspective and Conclusion

- 10.1 Concluding Recommendations and Analysis

- 10.2 Strategies for Market Potential

Scope of Report

| Aspects | Details |

|---|---|

By Type |

|

By Application |

|

By Architecture |

|

Report Licenses

Our Team

Frequently Asked Questions (FAQ):

What is the estimated market size of Machine condition monitoring in 2030?

+

-

Which type of Machine condition monitoring is widely popular?

+

-

What is the growth rate of Machine condition monitoring Market?

+

-

What are the latest trends influencing the Machine condition monitoring Market?

+

-

Who are the key players in the Machine condition monitoring Market?

+

-

How is the Machine condition monitoring } industry progressing in scaling its end-use implementations?

+

-

What product types are analyzed in the Machine condition monitoring Market Study?

+

-

What geographic breakdown is available in Global Machine condition monitoring Market Study?

+

-

Which region holds the second position by market share in the Machine condition monitoring market?

+

-

How are the key players in the Machine condition monitoring market targeting growth in the future?

+

-