Global High Pressure Die Casting Market - Industry Dynamics, Size, And Opportunity Forecast To 2032

Report ID: MS-370 | Chemicals And Materials | Last updated: Feb, 2025 | Formats*:

High Pressure Die Casting Report Highlights

| Report Metrics | Details |

|---|---|

| Forecast period | 2019-2032 |

| Base Year Of Estimation | 2024 |

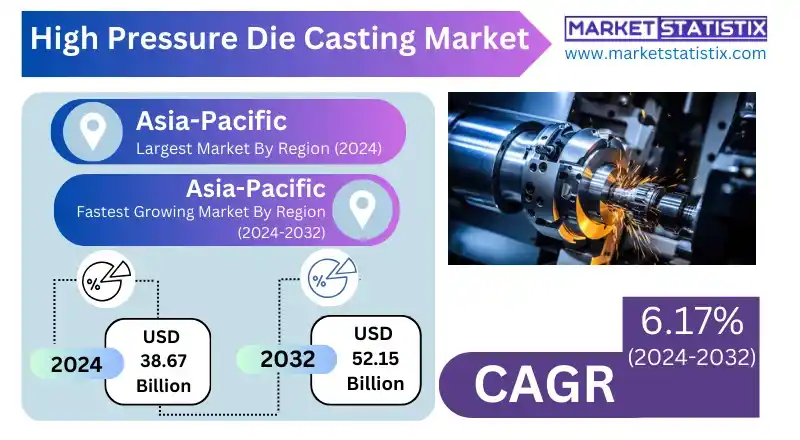

| Growth Rate | CAGR of 6.17% |

| Forecast Value (2032) | USD 52.15 Billion |

| By Product Type | Aluminum, Magnesium, Zinc |

| Key Market Players |

|

| By Region |

|

High Pressure Die Casting Market Trends

The High Pressure Die Casting (HPDC) industry is on an impressive growth path owing to the robust demand from the automotive, aerospace, and electronics sectors. The intense demand for fuel-efficient and less-polluting vehicles has fostered an exponential rise in the adoption of aluminium and magnesium die-cast parts. In addition to that, sustainability trends favouring the use of recycled alloys and energy-efficient manufacturing processes are affecting the HPDC market. Growing demand for HPDC components stems from the arrival of electric vehicles (EVs), as lightweight materials directly affect battery performance and range of vehicles. Asia-Pacific, mainly China and India, appears to be a major growth region with the establishment of manufacturing bases and increasing investment in infrastructure and industrial development. The HPDC industry seems to boost further growth as industries move towards cost-effective, high-precision metal components.High Pressure Die Casting Market Leading Players

The key players profiled in the report are KPSNC, Ryobi, Nemak, Ashok Minda, FAIST, EnginSoft, Aurrenak, GF Automotive, Chongqing Yujiang, Endurance Technologies, Ahresty, Alteams, Dynacast, Handtmann, Guangdong HongtuGrowth Accelerators

The high-pressure die casting (HPDC) market is primarily driven by the increased demand for lightweight and durable components in automotive and aerospace applications. Manufacturers must meet increasingly strict fuel efficiency and emission requirements, which have opened the floodgates for demand for complex, high-strength, and lightweight parts. HPDC is an economical method for producing such components with high precision and repeatability, becoming the preferred process for innovation-driven and environmentally conscious industries. The surge in electric vehicles (EVs) and renewable energy is another factor propelling the HPDC market, as these industries need specialised components with high structural integrity. Further demand is also supplied by the increasing use of aluminium and magnesium alloys, which provide higher strength-to-weight ratios for growth in applications in various industries.High Pressure Die Casting Market Segmentation analysis

The Global High Pressure Die Casting is segmented by Type, Application, and Region. By Type, the market is divided into Distributed Aluminum, Magnesium, Zinc . The Application segment categorizes the market based on its usage such as Engine Parts, Body Assemblies, Transmission Parts. Geographically, the market is assessed across key Regions like North America (United States, Canada, Mexico), South America (Brazil, Argentina, Chile, Rest of South America), Europe (Germany, France, Italy, United Kingdom, Benelux, Nordics, Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia, Southeast Asia, Rest of Asia-Pacific), MEA (Middle East, Africa) and others, each presenting distinct growth opportunities and challenges influenced by the regions.Competitive Landscape

The competition in the worldwide High-Pressure Die Casting (HPDC) market is on the rise, with key players concentrating on technological advancements, automation, and materials innovations as strong differentiators. Key players in the HPDC market include companies such as Nemak, GF Casting Solutions, Ryobi Limited, and Martinrea International, who benefit from valuable years of experience in lightweight metal casting, especially with components in aluminium, magnesium, and zinc. The automotive industry remains the most significant driver of HPDC demand, and the shift to EVs is further pressing the necessity for lightweight and strong components. Investments are being made by companies into newer technologies in die casting, including vacuum die casting and squeeze casting, to enhance product quality and reduce porosity, thereby meeting strict industry standards.Challenges In High Pressure Die Casting Market

Challenges abound within the promising prospects of the High-pressure Die Casting (HPDC) market. Among these, the high initial investment cost for HPDC machinery such as die-casting machines, dies, and auxiliary systems poses a major challenge. This is, in fact, a hindrance for small and medium enterprises (SMEs) trying to enter or upgrade their existing facilities in the market. Another hindrance relates to the inherent complexities of the HPDC process itself. To achieve consistently good part quality while minimising defects such as porosity, blisters, and cold shuts, a great deal of attention must be paid to many process parameters, including melt temperature, injection pressure, die temperature, and cooling rates. Deviations from control of any of these parameters may cause a substantial variation in part quality, thereby necessitating constant monitoring and adjustment.Risks & Prospects in High Pressure Die Casting Market

The global High Pressure Die Casting (HPDC) market offers ample opportunities for growth and innovation. In the first place, the automotive industry has a tremendous opportunity in HPDC due to the growing demand for lightweight components caused by the emergence of electric vehicles and strict regulations on fuel efficiency. It is this process that lends itself well to the production of complex and lightweight components such as engine blocks and transmission housings or structural components of improved performance and lesser emissions. With such a case, HPDC is also getting opportunities in other sectors such as aerospace, electronics, and consumer goods, which require complex precision components. Outsourcing of manufacturing operations, in turn, makes HPDC manufacturers stand tall in the global marketplace to meet the costs of increasingly demanded components that are high quality and low price.Key Target Audience

Major audience types for the HPDC market range from automotive manufacturers, aerospace and defence industries, and industrial machinery manufacturers. Automotive suppliers utilise HPDC the most because of their lightweight aluminium and magnesium components designed for improving fuel efficiency and reducing emissions. The demand for high-performance, die-cast light parts, such as battery housings and structural components, is rising owing to the introduction of electric vehicles in the market.,, Other sizeable target groups include manufacturers of consumer electronics, suppliers of construction equipment, and die-casting machine manufacturers. The consumer electronics sector benefits from HPDC for producing casings that are complex and durable for smartphones, laptops, and home appliances. Also, manufacturers of construction and heavy equipment use HPDC for strong parts related to hydraulic systems as well as structural applications. Die-casting machine manufacturers and suppliers of raw materials are also critical segments, since improvements in casting technologies and developments in raw materials can further bolster market growth.Merger and acquisition

In the high-pressure die casting market, mergers and acquisitions are occurring at a frantic rate as companies seek to increase geographic footprint and technological strength. Some of the more significant recent transactions include GF Casting Solutions' USD 184 million commitment to a new site in Georgia to manufacture large structural parts for the automotive market, particularly the e-mobility market. Additionally, in early 2024, Alutech Holding GmbH Co. KG acquired AE Group AG, marking a strategic milestone that reflects the industry's ongoing transformation and adaptation to modern manufacturing demands. As the market changes, the leading companies, Nemak and Rheinmetall AG, actively strategies cooperation and acquisition of more and more manufacturers as a way to guarantee their position in the market against a new competition of economies in the making. This trend is driven by the increasing demand for lightweight components, particularly for electric vehicles, which has pushed companies to innovate and adopt advanced manufacturing technologies. >Analyst Comment

The High Pressure Die Casting (HPDC) market is witnessing tremendous growth owing to the increasing demand for lightweight and high-precision components across industries: automotive has somewhat been a major contributor to the growth as manufacturers are relatively keen on using HPDC for producing complex parts like engine blocks, transmission cases, and shell structures for electric vehicle manufacturing. The whole trend is being backed by parameters such as weight reduction for vehicular fuel efficiency and increasing acceptance of electric vehicles.- 1.1 Report description

- 1.2 Key market segments

- 1.3 Key benefits to the stakeholders

2: Executive Summary

- 2.1 High Pressure Die Casting- Snapshot

- 2.2 High Pressure Die Casting- Segment Snapshot

- 2.3 High Pressure Die Casting- Competitive Landscape Snapshot

3: Market Overview

- 3.1 Market definition and scope

- 3.2 Key findings

- 3.2.1 Top impacting factors

- 3.2.2 Top investment pockets

- 3.3 Porter’s five forces analysis

- 3.3.1 Low bargaining power of suppliers

- 3.3.2 Low threat of new entrants

- 3.3.3 Low threat of substitutes

- 3.3.4 Low intensity of rivalry

- 3.3.5 Low bargaining power of buyers

- 3.4 Market dynamics

- 3.4.1 Drivers

- 3.4.2 Restraints

- 3.4.3 Opportunities

4: High Pressure Die Casting Market by Type

- 4.1 Overview

- 4.1.1 Market size and forecast

- 4.2 Aluminum

- 4.2.1 Key market trends, factors driving growth, and opportunities

- 4.2.2 Market size and forecast, by region

- 4.2.3 Market share analysis by country

- 4.3 Magnesium

- 4.3.1 Key market trends, factors driving growth, and opportunities

- 4.3.2 Market size and forecast, by region

- 4.3.3 Market share analysis by country

- 4.4 Zinc

- 4.4.1 Key market trends, factors driving growth, and opportunities

- 4.4.2 Market size and forecast, by region

- 4.4.3 Market share analysis by country

5: High Pressure Die Casting Market by Application / by End Use

- 5.1 Overview

- 5.1.1 Market size and forecast

- 5.2 Engine Parts

- 5.2.1 Key market trends, factors driving growth, and opportunities

- 5.2.2 Market size and forecast, by region

- 5.2.3 Market share analysis by country

- 5.3 Body Assemblies

- 5.3.1 Key market trends, factors driving growth, and opportunities

- 5.3.2 Market size and forecast, by region

- 5.3.3 Market share analysis by country

- 5.4 Transmission Parts

- 5.4.1 Key market trends, factors driving growth, and opportunities

- 5.4.2 Market size and forecast, by region

- 5.4.3 Market share analysis by country

6: High Pressure Die Casting Market by Region

- 6.1 Overview

- 6.1.1 Market size and forecast By Region

- 6.2 North America

- 6.2.1 Key trends and opportunities

- 6.2.2 Market size and forecast, by Type

- 6.2.3 Market size and forecast, by Application

- 6.2.4 Market size and forecast, by country

- 6.2.4.1 United States

- 6.2.4.1.1 Key market trends, factors driving growth, and opportunities

- 6.2.4.1.2 Market size and forecast, by Type

- 6.2.4.1.3 Market size and forecast, by Application

- 6.2.4.2 Canada

- 6.2.4.2.1 Key market trends, factors driving growth, and opportunities

- 6.2.4.2.2 Market size and forecast, by Type

- 6.2.4.2.3 Market size and forecast, by Application

- 6.2.4.3 Mexico

- 6.2.4.3.1 Key market trends, factors driving growth, and opportunities

- 6.2.4.3.2 Market size and forecast, by Type

- 6.2.4.3.3 Market size and forecast, by Application

- 6.2.4.1 United States

- 6.3 South America

- 6.3.1 Key trends and opportunities

- 6.3.2 Market size and forecast, by Type

- 6.3.3 Market size and forecast, by Application

- 6.3.4 Market size and forecast, by country

- 6.3.4.1 Brazil

- 6.3.4.1.1 Key market trends, factors driving growth, and opportunities

- 6.3.4.1.2 Market size and forecast, by Type

- 6.3.4.1.3 Market size and forecast, by Application

- 6.3.4.2 Argentina

- 6.3.4.2.1 Key market trends, factors driving growth, and opportunities

- 6.3.4.2.2 Market size and forecast, by Type

- 6.3.4.2.3 Market size and forecast, by Application

- 6.3.4.3 Chile

- 6.3.4.3.1 Key market trends, factors driving growth, and opportunities

- 6.3.4.3.2 Market size and forecast, by Type

- 6.3.4.3.3 Market size and forecast, by Application

- 6.3.4.4 Rest of South America

- 6.3.4.4.1 Key market trends, factors driving growth, and opportunities

- 6.3.4.4.2 Market size and forecast, by Type

- 6.3.4.4.3 Market size and forecast, by Application

- 6.3.4.1 Brazil

- 6.4 Europe

- 6.4.1 Key trends and opportunities

- 6.4.2 Market size and forecast, by Type

- 6.4.3 Market size and forecast, by Application

- 6.4.4 Market size and forecast, by country

- 6.4.4.1 Germany

- 6.4.4.1.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.1.2 Market size and forecast, by Type

- 6.4.4.1.3 Market size and forecast, by Application

- 6.4.4.2 France

- 6.4.4.2.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.2.2 Market size and forecast, by Type

- 6.4.4.2.3 Market size and forecast, by Application

- 6.4.4.3 Italy

- 6.4.4.3.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.3.2 Market size and forecast, by Type

- 6.4.4.3.3 Market size and forecast, by Application

- 6.4.4.4 United Kingdom

- 6.4.4.4.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.4.2 Market size and forecast, by Type

- 6.4.4.4.3 Market size and forecast, by Application

- 6.4.4.5 Benelux

- 6.4.4.5.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.5.2 Market size and forecast, by Type

- 6.4.4.5.3 Market size and forecast, by Application

- 6.4.4.6 Nordics

- 6.4.4.6.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.6.2 Market size and forecast, by Type

- 6.4.4.6.3 Market size and forecast, by Application

- 6.4.4.7 Rest of Europe

- 6.4.4.7.1 Key market trends, factors driving growth, and opportunities

- 6.4.4.7.2 Market size and forecast, by Type

- 6.4.4.7.3 Market size and forecast, by Application

- 6.4.4.1 Germany

- 6.5 Asia Pacific

- 6.5.1 Key trends and opportunities

- 6.5.2 Market size and forecast, by Type

- 6.5.3 Market size and forecast, by Application

- 6.5.4 Market size and forecast, by country

- 6.5.4.1 China

- 6.5.4.1.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.1.2 Market size and forecast, by Type

- 6.5.4.1.3 Market size and forecast, by Application

- 6.5.4.2 Japan

- 6.5.4.2.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.2.2 Market size and forecast, by Type

- 6.5.4.2.3 Market size and forecast, by Application

- 6.5.4.3 India

- 6.5.4.3.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.3.2 Market size and forecast, by Type

- 6.5.4.3.3 Market size and forecast, by Application

- 6.5.4.4 South Korea

- 6.5.4.4.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.4.2 Market size and forecast, by Type

- 6.5.4.4.3 Market size and forecast, by Application

- 6.5.4.5 Australia

- 6.5.4.5.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.5.2 Market size and forecast, by Type

- 6.5.4.5.3 Market size and forecast, by Application

- 6.5.4.6 Southeast Asia

- 6.5.4.6.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.6.2 Market size and forecast, by Type

- 6.5.4.6.3 Market size and forecast, by Application

- 6.5.4.7 Rest of Asia-Pacific

- 6.5.4.7.1 Key market trends, factors driving growth, and opportunities

- 6.5.4.7.2 Market size and forecast, by Type

- 6.5.4.7.3 Market size and forecast, by Application

- 6.5.4.1 China

- 6.6 MEA

- 6.6.1 Key trends and opportunities

- 6.6.2 Market size and forecast, by Type

- 6.6.3 Market size and forecast, by Application

- 6.6.4 Market size and forecast, by country

- 6.6.4.1 Middle East

- 6.6.4.1.1 Key market trends, factors driving growth, and opportunities

- 6.6.4.1.2 Market size and forecast, by Type

- 6.6.4.1.3 Market size and forecast, by Application

- 6.6.4.2 Africa

- 6.6.4.2.1 Key market trends, factors driving growth, and opportunities

- 6.6.4.2.2 Market size and forecast, by Type

- 6.6.4.2.3 Market size and forecast, by Application

- 6.6.4.1 Middle East

- 7.1 Overview

- 7.2 Key Winning Strategies

- 7.3 Top 10 Players: Product Mapping

- 7.4 Competitive Analysis Dashboard

- 7.5 Market Competition Heatmap

- 7.6 Leading Player Positions, 2022

8: Company Profiles

- 8.1 Alteams

- 8.1.1 Company Overview

- 8.1.2 Key Executives

- 8.1.3 Company snapshot

- 8.1.4 Active Business Divisions

- 8.1.5 Product portfolio

- 8.1.6 Business performance

- 8.1.7 Major Strategic Initiatives and Developments

- 8.2 Aurrenak

- 8.2.1 Company Overview

- 8.2.2 Key Executives

- 8.2.3 Company snapshot

- 8.2.4 Active Business Divisions

- 8.2.5 Product portfolio

- 8.2.6 Business performance

- 8.2.7 Major Strategic Initiatives and Developments

- 8.3 Ashok Minda

- 8.3.1 Company Overview

- 8.3.2 Key Executives

- 8.3.3 Company snapshot

- 8.3.4 Active Business Divisions

- 8.3.5 Product portfolio

- 8.3.6 Business performance

- 8.3.7 Major Strategic Initiatives and Developments

- 8.4 Nemak

- 8.4.1 Company Overview

- 8.4.2 Key Executives

- 8.4.3 Company snapshot

- 8.4.4 Active Business Divisions

- 8.4.5 Product portfolio

- 8.4.6 Business performance

- 8.4.7 Major Strategic Initiatives and Developments

- 8.5 Ryobi

- 8.5.1 Company Overview

- 8.5.2 Key Executives

- 8.5.3 Company snapshot

- 8.5.4 Active Business Divisions

- 8.5.5 Product portfolio

- 8.5.6 Business performance

- 8.5.7 Major Strategic Initiatives and Developments

- 8.6 Endurance Technologies

- 8.6.1 Company Overview

- 8.6.2 Key Executives

- 8.6.3 Company snapshot

- 8.6.4 Active Business Divisions

- 8.6.5 Product portfolio

- 8.6.6 Business performance

- 8.6.7 Major Strategic Initiatives and Developments

- 8.7 Dynacast

- 8.7.1 Company Overview

- 8.7.2 Key Executives

- 8.7.3 Company snapshot

- 8.7.4 Active Business Divisions

- 8.7.5 Product portfolio

- 8.7.6 Business performance

- 8.7.7 Major Strategic Initiatives and Developments

- 8.8 FAIST

- 8.8.1 Company Overview

- 8.8.2 Key Executives

- 8.8.3 Company snapshot

- 8.8.4 Active Business Divisions

- 8.8.5 Product portfolio

- 8.8.6 Business performance

- 8.8.7 Major Strategic Initiatives and Developments

- 8.9 Handtmann

- 8.9.1 Company Overview

- 8.9.2 Key Executives

- 8.9.3 Company snapshot

- 8.9.4 Active Business Divisions

- 8.9.5 Product portfolio

- 8.9.6 Business performance

- 8.9.7 Major Strategic Initiatives and Developments

- 8.10 Ahresty

- 8.10.1 Company Overview

- 8.10.2 Key Executives

- 8.10.3 Company snapshot

- 8.10.4 Active Business Divisions

- 8.10.5 Product portfolio

- 8.10.6 Business performance

- 8.10.7 Major Strategic Initiatives and Developments

- 8.11 KPSNC

- 8.11.1 Company Overview

- 8.11.2 Key Executives

- 8.11.3 Company snapshot

- 8.11.4 Active Business Divisions

- 8.11.5 Product portfolio

- 8.11.6 Business performance

- 8.11.7 Major Strategic Initiatives and Developments

- 8.12 GF Automotive

- 8.12.1 Company Overview

- 8.12.2 Key Executives

- 8.12.3 Company snapshot

- 8.12.4 Active Business Divisions

- 8.12.5 Product portfolio

- 8.12.6 Business performance

- 8.12.7 Major Strategic Initiatives and Developments

- 8.13 Chongqing Yujiang

- 8.13.1 Company Overview

- 8.13.2 Key Executives

- 8.13.3 Company snapshot

- 8.13.4 Active Business Divisions

- 8.13.5 Product portfolio

- 8.13.6 Business performance

- 8.13.7 Major Strategic Initiatives and Developments

- 8.14 EnginSoft

- 8.14.1 Company Overview

- 8.14.2 Key Executives

- 8.14.3 Company snapshot

- 8.14.4 Active Business Divisions

- 8.14.5 Product portfolio

- 8.14.6 Business performance

- 8.14.7 Major Strategic Initiatives and Developments

- 8.15 Guangdong Hongtu

- 8.15.1 Company Overview

- 8.15.2 Key Executives

- 8.15.3 Company snapshot

- 8.15.4 Active Business Divisions

- 8.15.5 Product portfolio

- 8.15.6 Business performance

- 8.15.7 Major Strategic Initiatives and Developments

9: Analyst Perspective and Conclusion

- 9.1 Concluding Recommendations and Analysis

- 9.2 Strategies for Market Potential

Scope of Report

| Aspects | Details |

|---|---|

By Type |

|

By Application |

|

Report Licenses

Our Team

Frequently Asked Questions (FAQ):

What is the estimated market size of High Pressure Die Casting in 2032?

+

-

Which type of High Pressure Die Casting is widely popular?

+

-

What is the growth rate of High Pressure Die Casting Market?

+

-

What are the latest trends influencing the High Pressure Die Casting Market?

+

-

Who are the key players in the High Pressure Die Casting Market?

+

-

How is the High Pressure Die Casting } industry progressing in scaling its end-use implementations?

+

-

What product types are analyzed in the High Pressure Die Casting Market Study?

+

-

What geographic breakdown is available in Global High Pressure Die Casting Market Study?

+

-

Which region holds the second position by market share in the High Pressure Die Casting market?

+

-

Which region holds the highest growth rate in the High Pressure Die Casting market?

+

-